Last Updated APRIL 2025

Strategies for Reducing Germ Spread in Industrial Facilities

Proactive hygiene management is essential in industrial facilities to minimize downtime, reduce costs and protect productivity. By targeting high-risk areas and optimizing cleaning protocols, you can address hidden risk that safeguard operations. Discover strategies to keep your facility running at peak performance.

Industrial facilities operate under constant pressure to meet production demands, but one often-overlooked threat to efficiency is the spread of germs. Small lapses in hygiene can disrupt production schedules, increase absenteeism and lead to costly delays. By addressing these risks proactively, facilities can keep operations smooth and efficient.

Unplanned downtime already costs industrial manufacturers as much as $50 billion annually, with shutdowns — scheduled or not — consuming 1% to 10% of available production time.1 Hygiene isn’t just about cleanliness; it’s about operational continuity.

Implementing the right practices can help reduce germ spread, protect employee health and maintain compliance, all while safeguarding productivity.

Identifying and Addressing Hidden Hygiene Risks

Operational efficiency in industrial facilities hinges on addressing a range of risks and hygiene is often overlooked. Subpar practices can lead to absenteeism, compliance challenges and disruptions that directly impact uptime and operational flow.

High-touch surfaces like machinery controls, shared tools and PPE stations are key areas for germ transfer. Breakrooms, locker rooms and vending machines also become high-risk zones during shift changes, when congestion increases the likelihood of contamination.

Conducting a targeted risk assessment helps uncover these vulnerabilities. Mapping employee workflows and monitoring shared space usage during peak periods can identify touchpoints — such as time clocks, handrails or equipment controls — that require more frequent cleaning.

Prioritizing hygiene protocols in these areas reduces germ spread, limits absenteeism and protects productivity.

Practical Tips and Strategies to Minimize Germ Spread

Hygiene isn’t just about cleanliness; it’s a strategic tool to protect uptime, reduce costs and support productivity. By focusing on these practical strategies, facilities can address key risks and optimize operations.

Enhanced Cleaning Protocols

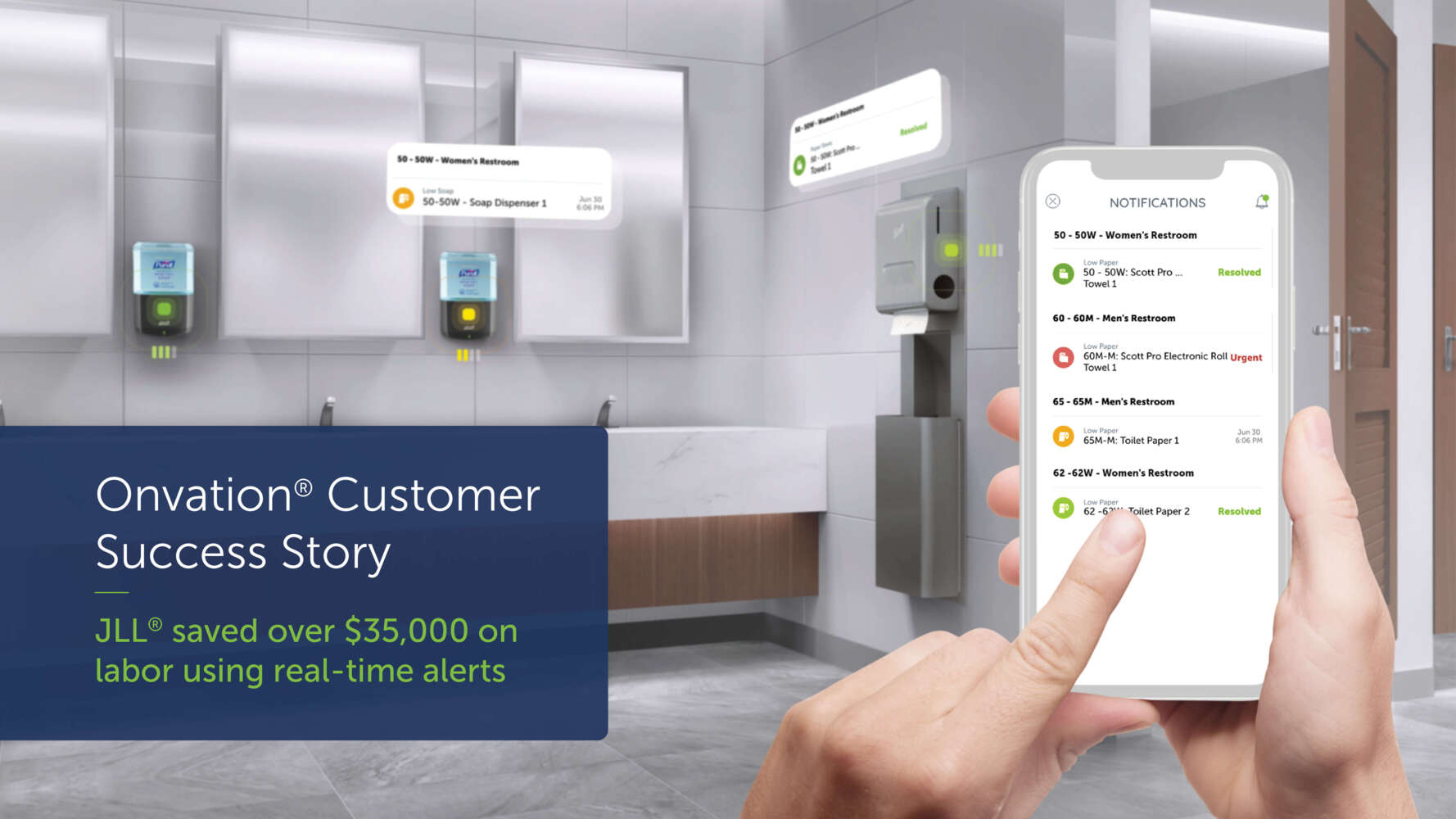

- Tailored cleaning schedules: Cleaning routines should be guided by actual usage patterns rather than assumptions. Smart restroom solutions like Onvation® provide real-time insights, helping prioritize high-traffic areas and allocate resources effectively.

- Task-specific cleaning tools: Reusable rags often introduce risks like cross-contamination and hidden labor costs for washing. Switching to single-use wipes ensures a cleaner, more reliable solution, reducing contamination risks and streamlining cleaning processes. Learn more about the myths versus facts of reusable rags and single-use wipes.

High-Touch Surface Management

- Focus on shared surfaces: Shared surfaces like machinery controls, door handles and breakroom tables are high-risk zones for contamination. Regular cleaning and disinfection reduce germ transfer, ensuring a more hygienic work environment and uninterrupted workflows.

- Hands-free dispensers: Touchless systems help minimize germ transfer by eliminating shared touchpoints in high-traffic zones. These solutions also make hygiene practices more convenient, reducing illness-related disruptions and supporting productivity.

Driving Compliance Through Culture and Accessibility

- Leadership sets the standard: Managers who visibly prioritize hygiene create a culture where cleanliness is a shared responsibility. This approach motivates employees to uphold best practices.

- Link Hygiene to Productivity: Hygiene directly supports uptime by reducing absenteeism and minimizing disruptions. Reinforce this connection to help employees see how their actions contribute to overall operational success.

- Accessible hygiene tools: Strategically placed hygiene stations near entrances, shared equipment and breakrooms make it easier for employees to maintain hygiene standards.

Monitoring and Continuous Improvement

Maintaining hygiene standards requires ongoing effort and adaptability. Combining data-driven insights, employee feedback and proactive adjustments ensures practices remain effective and aligned with operational goals.

Key Metrics to Monitor

Track these metrics to evaluate hygiene practices and identify gaps:

- Hygiene audit scores to measure compliance with established protocols.

- Absenteeism rates to assess the impact of hygiene efforts on employee health.

- Incident reports for workplace illness outbreaks or contamination events.

- Supply usage patterns to ensure hygiene stations remain stocked with essential products.

Predictive analytics can also identify trends, such as increased cleaning needs during flu season, enabling managers to better anticipate risks and prevent downtime.

Engaging Employees for Real-World Insights

Employees provide invaluable feedback on what works and where improvements are needed. Programs like hygiene ambassadors, suggestion boxes or quick team check-ins can highlight overlooked inefficiencies. Acting on this feedback not only strengthens hygiene practices but also fosters accountability.

Adapting Practices for Long-Term Success

Effective hygiene protocols should evolve to meet your changing needs. Regular evaluations guide adjustments, such as:

- Increasing disinfection during peak illness periods.

- Expanding touchless technology in high-traffic areas.

- Updating training programs to address emerging challenges or compliance gaps.

Proactive Hygiene and Productivity are Linked

Hygiene is more than a routine — it’s a critical factor in maintaining efficient, uninterrupted operations. Addressing facility hygiene proactively reduces illness and helps prevent costly disruptions.

When hygiene practices are built into the fabric of daily operations, facilities benefit from fewer setbacks, healthier teams and optimized workflows. A cleaner facility isn’t just about today — it’s the foundation for long-term success.

Ready to enhance your facility’s hygiene standards?

Explore our tailored hygiene solutions to help you stay compliant, enhance safety and streamline operations, allowing you to focus on keeping your operations running smoothly.