Last Updated APRIL 2025

The Hidden Hygiene Risks of Breakrooms and Shared Spaces in Industrial Facilities

Overlooked hygiene risks in shared spaces can impact productivity, compliance and efficiency. Learn how to tackle immediate hygiene gaps, reduce downtime and build a long-term strategy that keeps your facility running smoothly.

Industrial facilities prioritize efficiency, safety and compliance, yet shared spaces often go overlooked in hygiene strategies. While production areas follow strict sanitation protocols, breakrooms, locker rooms and restrooms don’t always receive the same attention — despite constant use by employees.

During a shift change, workers touch vending machines, coffee stations, lockers and restrooms in quick succession. Without effective cleaning protocols and proper hand hygiene, germs can spread quickly, increasing absenteeism and slowing down operations.

Absenteeism costs U.S. businesses $225 billion annually in lost productivity.1 In industrial facilities, where labor availability directly impacts production, clean, well-stocked shared spaces are essential to keeping operations running smoothly.

By prioritizing hygiene in these high-traffic areas, facility managers can help reduce germ spread, support workforce well-being and minimize costly disruptions.

Identifying High-Risk Shared Spaces

Effective hygiene management in industrial environments begins by identifying high-risk areas, such as shared spaces, which can increase the risk of germ transfer and contamination.

| Space | Key Risks | Key Risks |

|---|---|---|

| Breakrooms | Frequent hand contact on tables, vending machines and coffee stations leads to rapid germ spread. Peak congestion during shift changes increases contamination risk. |

|

| Locker Rooms | Moisture and frequent handling of lockers, benches and PPE create conditions for bacteria growth. Shared PPE storage increases the risk of cross-contamination. |

|

| Restrooms | High-touch points (door handles, toilet flush levers, faucets) facilitate germ spread. Jet air dryers increase airborne bacteria. Inconsistent stock of soap/paper towels leads to hygiene lapses. |

|

| Shared Equipment & Workstations | Tools, machinery controls, printers and phones see high contact across multiple employees. Infrequent cleaning allows germs to accumulate. |

|

The True Cost of Poor Hygiene in Shared Spaces

Hygiene in shared spaces isn’t just about cleanliness — it’s a business issue with real financial consequences. When these areas are neglected, the impact extends beyond occasional illnesses:

- Operational Slowdowns: Absenteeism due to illness results in 5-20% productivity losses in many industrial settings.2

- Higher Costs from Disruptions: Unplanned downtime costs manufacturers an estimated $50 billion annually, with staffing shortages being a major contributor.3

- Regulatory Compliance Risks: OSHA violations related to poor sanitation could result in fines exceeding $15,000 per infraction.4

The bottom line: poor hygiene isn’t just about meeting safety and regulatory standards, it impacts productivity, efficiency and cost control.

Where to Focus Immediate Fixes

Facility managers are already stretched thin, so tackling every hygiene gap at once isn’t realistic. Instead, prioritizing the highest-impact areas first ensures quick improvements with measurable results.

- Target High-Risk Areas First: Breakrooms, restrooms and shared workstations require the most urgent attention.

- Address Hygiene Gaps that Slow Operations: If absenteeism is rising, reinforcing hand hygiene and sanitization protocols in breakrooms and locker rooms is a smart first step.

- Ensure Compliance in Critical Areas: Restrooms and high-traffic zones should be upgraded with touchless dispensers and real-time supply monitoring to prevent shortages and maintain OSHA standards.

Fixing hygiene gaps quickly reduces immediate risk, but for long-term success, facilities need structured hygiene programs. The next section covers how to make hygiene a built-in part of facility operations.

Building a Long-Term Hygiene Strategy: Best Practices for Sustainable Facility Hygiene

Developing a clean and compliant industrial environment begins with a proactive hygiene strategy that addresses all potential risks.

Enhanced Cleaning Protocols

1. Use Smart Scheduling to Improve

Efficiency

Time-based cleaning schedules often fail to account for real usage patterns in high-traffic areas like restrooms.

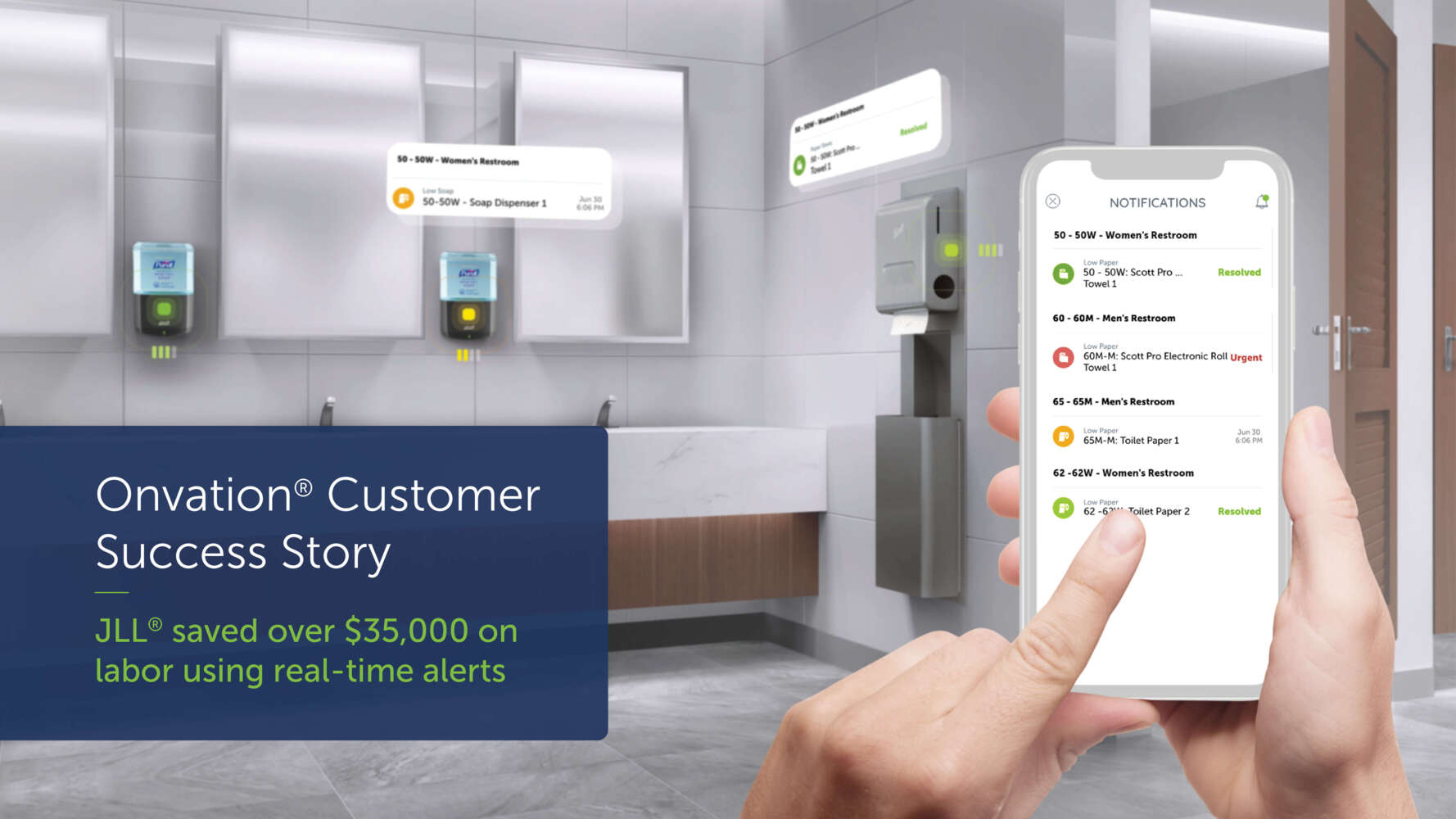

Smart restroom solutions like Onvation® provide

real-time data on facility usage, allowing teams to focus cleaning

efforts where they’re needed most while ensuring critical restroom supplies remain stocked.

2. Standardize Cleaning Protocols Across

Teams

Inconsistent cleaning methods create hygiene gaps, increasing the risk of cross-contamination. Establish

standardized protocols to ensure cleaning teams use the right products for each surface and follow uniform

disinfection procedures.

3. Choose the Right Cleaning Tools

Reusable rags can spread bacteria rather than remove it, creating hidden contamination risks. Switching to

single-use wipes provides a more effective, hygienic alternative for breakrooms, workstations and shared equipment.

Discover three independent studies that confirm the benefits of single-use wipes over reusable rags.

Optimizing Accessibility & Compliance

1. Strategically Position Hygiene

Stations

Employees are more likely to follow hygiene practices when supplies are conveniently located. Placing sanitization

stations at breakroom entrances, locker room exits and shared equipment zones ensures hygiene is seamlessly

integrated into daily routines.

2. Simplify Compliance with Touchless

Solutions

High-touch restroom fixtures contribute to germ spread. Installing touchless dispensers and single-use paper towel

systems reduces contamination risks and improves hygiene compliance by minimizing unnecessary contact.

3. Monitor Hygiene Supplies in

Real-Time

Running out of critical hygiene supplies leads to lapses in cleanliness, but overstocking or premature replenishment

can create unnecessary waste. Smart restroom

solutions like Onvation® provide real-time tracking of supply usage, allowing facility managers to identify

usage patterns and restock efficiently before shortages occur.

Building a Culture of Hygiene Accountability

1. Incorporate Hygiene Training into Safety

Programs

Employees often

overlook hygiene’s critical impact on productivity. Incorporating hygiene best practices into safety training

reinforces its direct role in reducing downtime, preventing illness-related absenteeism and maintaining

operational efficiency.

2. Empower Employees with Hygiene

Ambassadors

A strong hygiene culture starts with leadership. Designate hygiene champions within key teams to help reinforce

compliance, model best practices and encourage peer accountability across shifts.

3. Use Visual Cues to Maintain

Awareness

Hygiene is most effective when it becomes second nature. Post clear, high-visibility signage in shared spaces to

remind employees about proper handwashing techniques (because yes, 95% of adults wash their hands incorrectly), surface

disinfection and supply locations.

How to Measure Hygiene Improvements

Tracking hygiene effectiveness is essential for continuous improvement. Facility managers should monitor:

- Hygiene audit scores for compliance with cleaning protocols.

- Absenteeism rates before and after implementing hygiene best practices.

- Employee feedback through surveys on cleanliness perceptions.

- Supply usage data, leveraging Onvation® to ensure efficient resource allocation and prevent product shortages.

These KPIs help validate whether hygiene investments are delivering measurable business benefits.

Making Hygiene a Shared Responsibility

Shared spaces play a crucial role in industrial facilities, yet they remain some of the most under-addressed hygiene risks. Implementing proactive hygiene strategies isn’t just about maintaining a cleaner environment — it’s about safeguarding workforce health, operational efficiency and compliance.

By prioritizing needs-based cleaning, increasing accessibility and reinforcing hygiene education, facility managers can create an environment that minimizes disruptions, reduces costs and supports a healthier, more productive workforce.

Optimize Hygiene. Maximize Productivity. Stay Compliant.

Reduce downtime, meet regulatory standards and keep operations running smoothly with hygiene solutions designed for industrial environments. See how the right products can enhance efficiency and workplace safety.

2 Hemp, P. (2014, August 1). Presenteeism: At Work—But out of it. Harvard Business Review. https://hbr.org/2004/10/presenteeism-at-work-but-out-of-it

3 Deloitte. (n.d.). Predictive maintenance and the smart factory. https://www2.deloitte.com/content/dam/Deloitte/us/Documents/process-and-operations/us-cons-predictive-maintenance.pdf

4 OSHA Violation Penalty Information