Last Updated JULY 2023

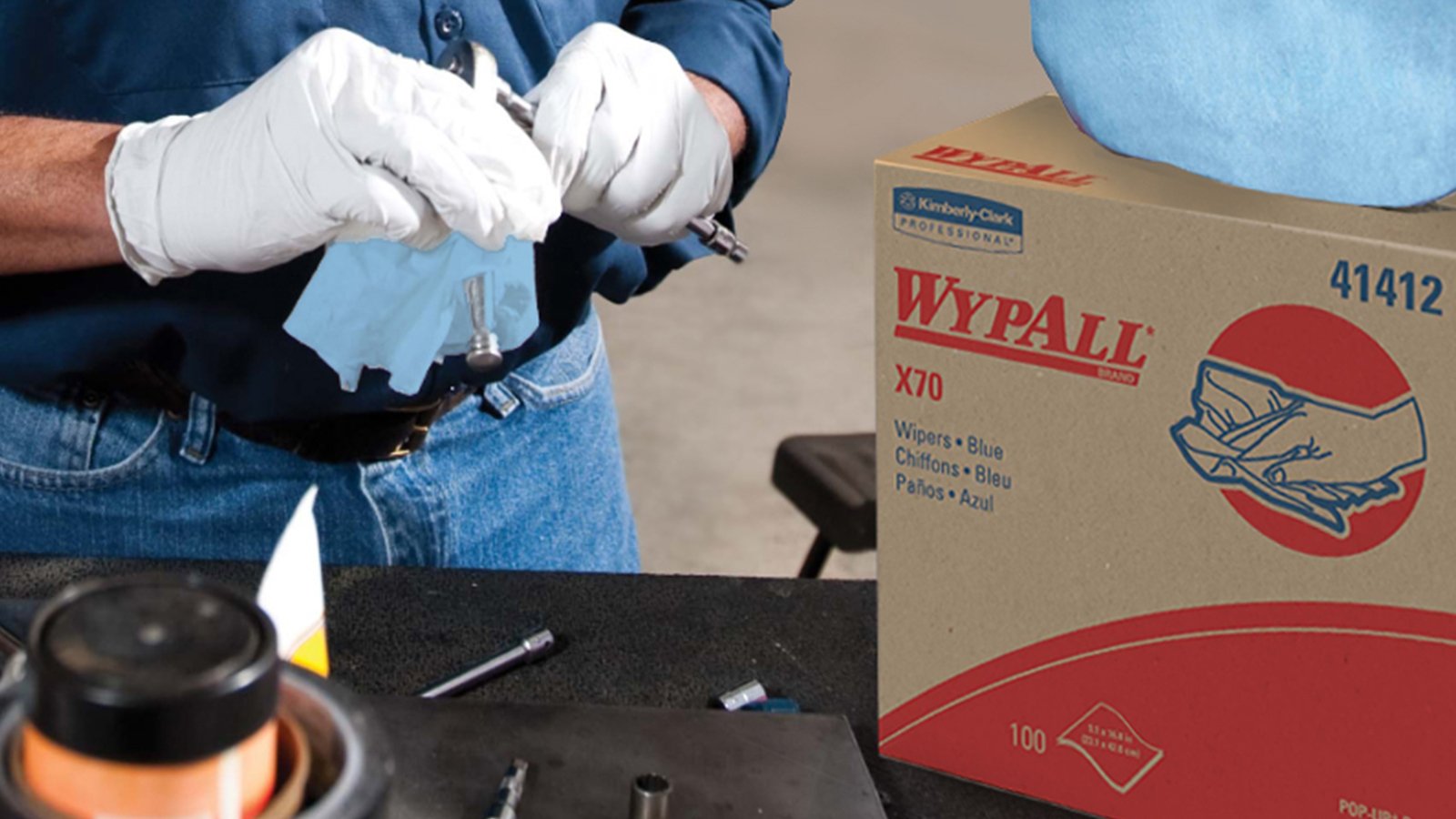

Three Basic Steps to Effective Cleaning

Good facilities, production and quality managers know that a methodical approach to cleaning often consumes fewer man-hours and resources. Adopting certain best practices can help make cleaning more efficient and create the best results.

Below are three basic rules that aspiring managers can adopt when working on your manufacturing floor:

1.Keep workspaces organized: By keeping parts and tools, including cleaning tools, where they can be easily located, it can help improve overall productivity and efficiency.

2.Address spills quickly: With tools placed at its allocated spots, reaching out for those wipes can quickly clean up any spills.

3.Have a regular equipment maintenance and cleaning schedules: With regular schedules, you may reduce machine breakdowns and in turn reduce repair costs. By keeping your workspaces equiped with cleaning supplies like wipes, your team can wipe any dust or debris from surfaces within an arm's reach.

Get in touch with our experts to review your cleaning protocols and incorporate wipes in your day-to-day.

Note: Information contained here are recommended best practices, and do not supersede any recommendations or regulations mandated by local laws and regulations.