Last Updated JULY 2023

Make Your Workplace Safer By Minimizing These Hazards

How well do you understand the significance of managing potential hazards responsibly? Here are some strategies to address them in your workplace.

Ensuring efficiency on the floor of the automotive manufacturing and maintenance industries is important as a slip in control can cause extreme consequences. The industries also produce a wide range of waste, some of which is hazardous1. Here are some examples of hazards and strategies for managing your waste stream while increasing efficiency.

Significant Hazards Faced On The Daily

A factory floor is a bustling place of manufacturing robots and equipment. It contains moving machinery and thousands of employees working in collaboration.

On top of that, the waste and hazards in the automotive manufacturing and maintenance industries are aplenty1. They include defects, transport waste, inventory waste and motion waste which leads to time wasted and a dip in productivity. Additionally, they may injure and endanger employees as well. It isn't easy to maintain this complex supply chain where employees' health and safety are of primary importance.

Here are some of the problems2 that employees may face:

- Trip hazards due to the high volume of used rags lying around the workplace

- Dirty surfaces can cause contamination and damage, leading to rework

- Potential sources of contamination for sensitive components due to the reusing of dirty rags

- Contamination risk in heavy maintenance hangar from dirty tissue rolls lying around without proper storage

- Frayed cotton rags risk causing paint defects due to lint and debris left behind

- Uncontrolled solvent usage may lead to avoidable chemical waste and may expose employees to harmful chemicals

- Potential chemical exposure hazard on employees' hands and skin due to improper management of solvents, sealants and adhesives used

- Employees' time may be wasted due to rags and wipes being stored away from their workstations

- Using incorrect, low dexterity gloves when handling chemical hazards which offer no chemical protection for employees

Solutions For A Safer Workplace

A workplace injury can have a domino effect on the productivity of your factory. Besides educating your employees on safety precautions, you can also provide risk minimization solutions for various workplace dangers and problems. Reduce hazard risks by considering implementing some of these strategies2:

- Dispensing of products near the point of use with visual management tools for placement and replenishment

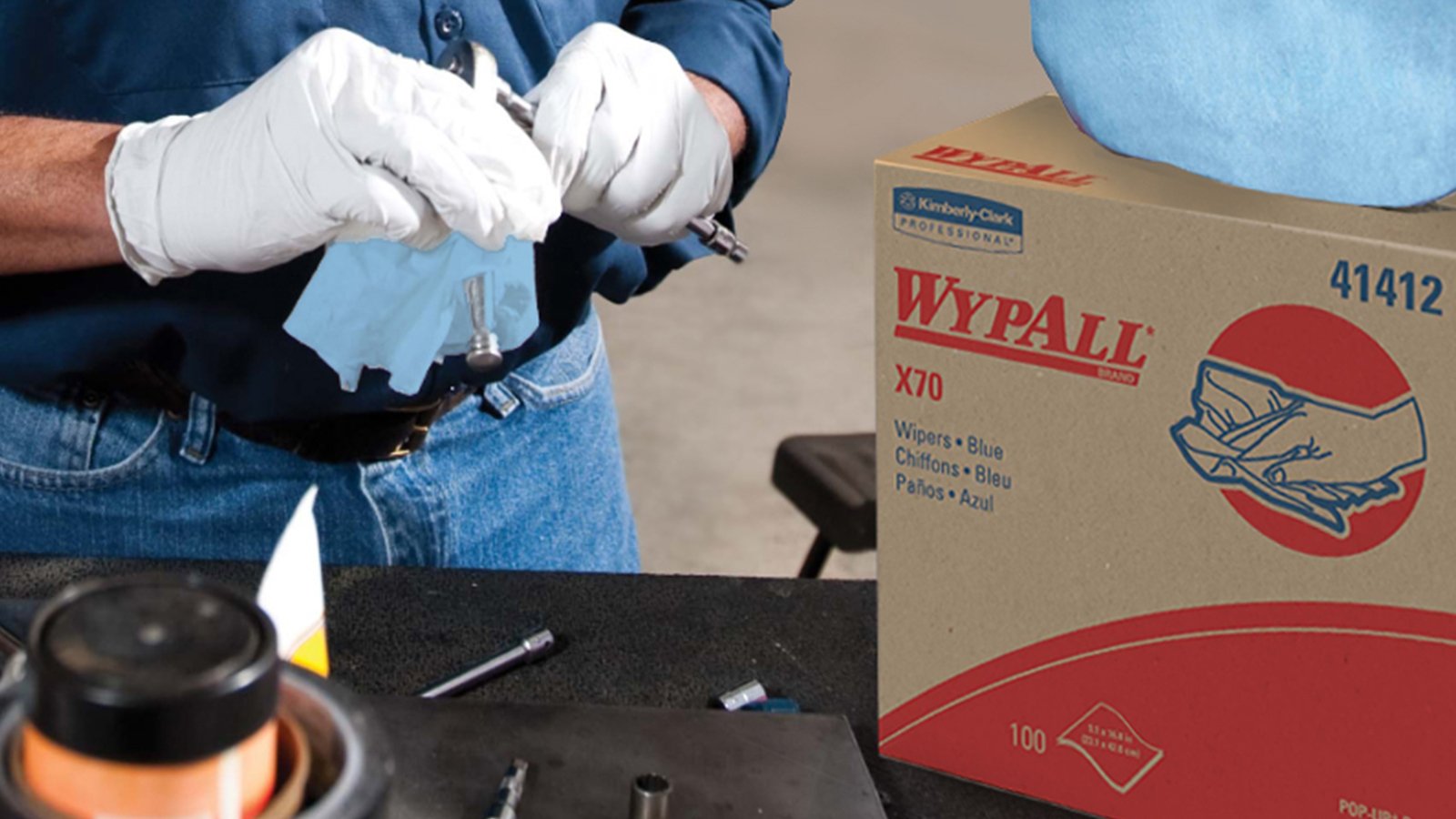

- Replacement of easily frayed rags with portable manufactured wipes for use in maintenance tasks

- Use heavy-duty wipes instead of rags to reduce contamination risks like lint and debris in engine components

- Implement standard solvent usage practices and products to reduce exposure to chemicals and costs associated with wasted solvent

- Upgrading of gloves with a high-dexterity, chemical resistant gloves

The Importance Of Risk Management Practices

Hazards are plentiful1´2 in the automotive manufacturing and maintenance industries. Workers in those industries can suffer repercussions if they operate in unsafe work environments. On the other hand, employees who come into contact with hazards without following proper safety protocols can suffer potential harm. It is unwise to underestimate the exposed risk to end-users posed by improper waste management.

Workplace safety should be highlighted from day one, even before employees learn about the manufacturing process. Those who work in those industries should be trained with essential safety management. Safety is a continuous effort that helps ensure an efficient workplace. It might take some planning and changes for your business to implement various waste management improvements.

To learn about how you can reduce waste and hazard risks on your automotive manufacturing and maintenance floor, speak with our experts today.

1 Source: “Motor Freight and Railroad Transportation” and “Vehicle Maintenance” industries at: https://www.epa.gov/hwgenerators/typical-wastes-generated-industry-sectors

2 Based on observations done by Kimberly-Clark at various customer manufacturing sites between 2012 and 2014, across various countries